Experts in Heating for the Vacuum Industry

Experts in Heating for the Vacuum Industry

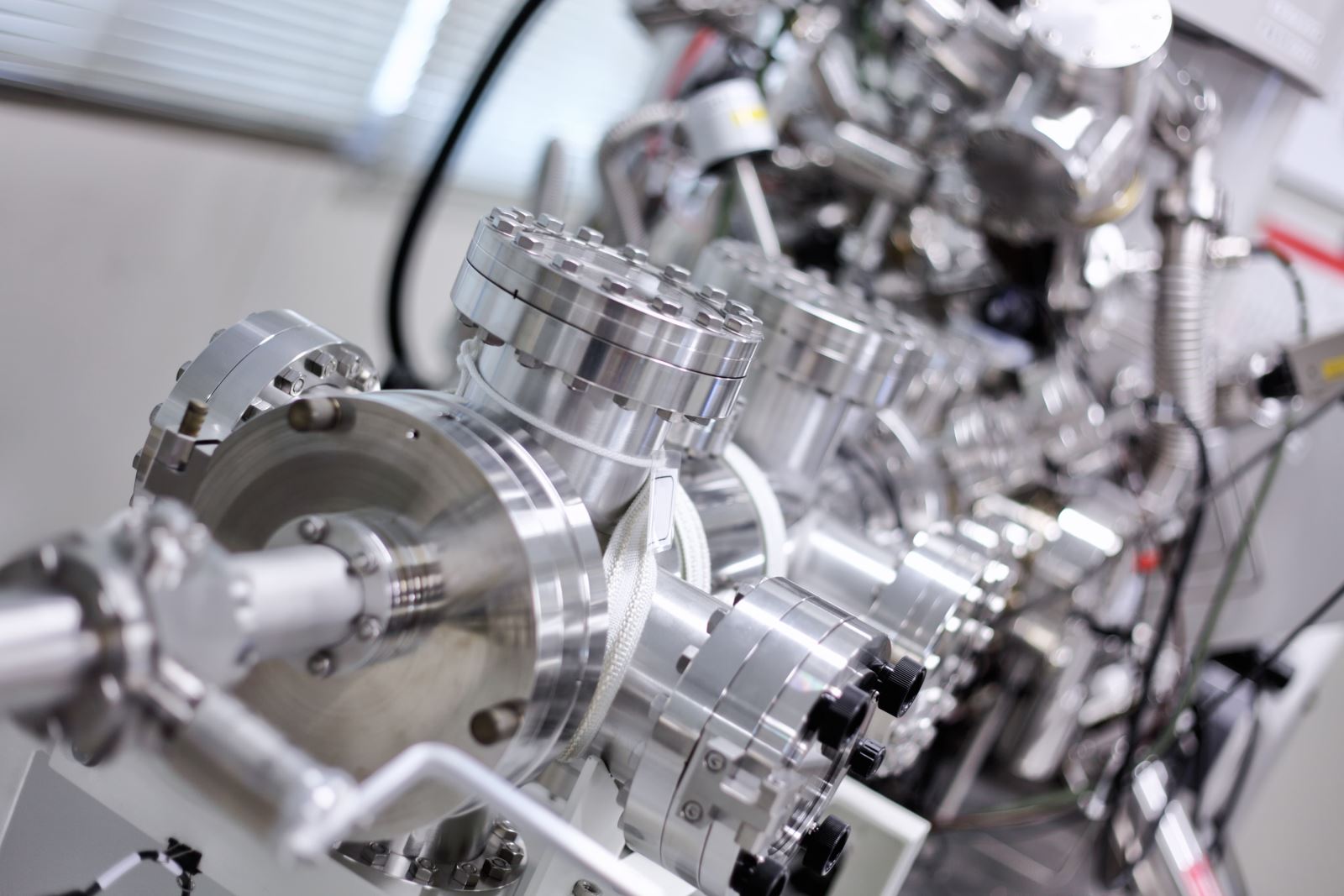

If you’re working in the semi-conductor industry, you’ll no doubt appreciate the importance of effective high temperature plate heaters when it comes to choosing the right products for vacuum operations. With temperature being our business, at Okazaki we’ve always specialised in delivering solutions that have the capability to operate in extreme conditions. Certainly superior performance and the ability to cater for a uniform surface temperature is absolutely key.

We know how you need solutions that adhere to very specific conditions. All of our plate heaters are fully manufactured and assembled at our dedicated facilities. As we use our own carefully designed mineral insulated heater thermocouples, you can be guaranteed that each unit is finished to the highest of standards. In fact, all of our units are extensively tested to ensure uniformity within 1% to make sure that they have the capability to operate to 1000°C.

We also recognise that one product doesn’t fit all. Which is why we’re able to offer a range of plate heaters in a variety of shapes and sizes – including round and square. Materials-wise, we’re able to give you a wide choice including aluminium Inconel alloys and stainless steel, amongst others.

Our Aeroheat heater in particular is a long-life mineral insulated metal sheathed heater. Having been manufactured from a single diameter cable with no internal joins to eliminate mechanical failure points, the heater assemblies benefit from an integrated un-heated cold section. This means that there’s no additional need for costly infrastructure such as water cooling pipe work or alternative systems to maintain lower temperatures. In addition to this, you’ll also look forward to a reduction in overall plant running cost – helping you to meet environment operating costs.

You can simply integrate the Aeroheat heater and its terminations into sealing flanges or ports, which means that full sealing is maintained – even in the highest of vacuum atmospheres.

Particularly beneficial in all forms of deposition equipment, the Aeroheat makes for an excellent choice in ALD, CVD, ion plating and sputtering. Precise temperature control can soon be achieved by arranging a set of multiple panel heaters. This is even possible with the largest of today’s and future glass substrates including Generation 10 and above. Plus, a circuit partition is also possible in order to compensate for any local temperature decrease caused by the carriers.